— CASE CENTER —

Alcohol Packaging Cosmetic Product Packaging Electronic Product Packaging Digital Printing Industry Other

Service Hotline:

Service Hotline:

0755-28748885

home > case > Common Problem

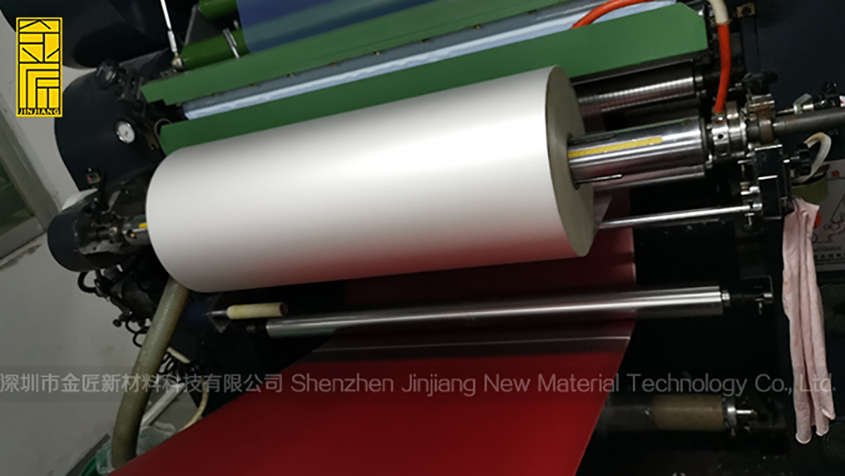

Lamination is one of the common surface processes in packaging and printing. It can not only protect the printed product, but also increase the surface effect of the printed product and improve the quality of the printed product! However, in the process of lamination, some problems of poor lamination are occasionally encountered, such as weak lamination, wrinkles, air bubbles, curling, etc. Now let's share and exchange about the problem of weak lamination:

weak lamination: this kind of bad phenomenon often occurs in the printing lamination with large area and large ink level. The main manifestations are: after die-cutting, the edge of the laminated film is opened and warped, the die-cutting indentation line and the embossing reverse white. Ironing and embossing reverse white, etc. The reasons for this are:

1. The solid content of the glue is low or the amount of glue is small, so that it cannot be well attached to the printing paper! The weak lamination caused by this situation is easy to fall off no matter what material it is, or what kind of pictures and texts are printed. Especially for some paper with large printing powder and not smooth surface and special film with thick film material, the selected glue also has certain requirements. For our " shiny starry frosted lamination film",

which is suggested to use high viscosity embossing glue!

2. When printing, the ink is not completely dried or the solidity after drying is not good, that causes the film reverse white. It is recommended to wait for 4-8 hours after printing, so that the ink on the surface of the printed sheet is completely cured and dried before laminating.

3. The surface tension of the printing material is too low, which leads to the weak adhesion of the ink and the weak lamination. It is recommended to consider online corona or primer coating to increase the surface tension of the material before printing.

4. In order to achieve high-quality results for the surface lamination of products with large area, large ink level and high requirements, it is recommended to adjust the appropriate amount of glue, temperature, speed and tension before the formal lamination

Service Hotline

0755-28748885Shenzhen Jinjiang New Material Technology Co., Ltd.

http://www.jinjiangco.com/

Contact: Mr. Wu +86 13922888253 ; Ms Liu +86 19820258885

Tel: 0755-28748885

Email: 2499404079@qq.com

Address: Building 2, No. 57, Fengguan Road, Tiantangwei, Fenggang Town, Dongguan City

Official WeChat

Official WeChat

WeChat

WeChat

2016 © Shenzhen Jinjiang New Material Technology Co., Ltd. Copyright all ICP for the 325356242-1